- Product: Sodium Gluconate

- Form: White crystalline powder

- Purity %: ≥: 98% min

- PH Value: 6.2~7.8

- CAS No.: 527-07-1

- MF: C6H11NaO7

Sodium gluconate is the sodium salt compound of gluconic acid. In terms of appearance, it is a white crystalline powder. And this product is easily soluble in water, and its aqueous solution is neutral to slightly alkaline; it is insoluble in organic solvents such as ethanol and ether. Generally speaking, 98% pure sodium gluconate has less impurities and its dissolution rate is more than 30% faster than that of low-purity products, without any precipitation residue.

As an important chemical raw material, sodium gluconate has a wide range of applications. For example, it is mainly used in construction industry, textile printing industry, metal surface treatment, water treatment industry, food industry, pharmaceutical industry, etc.

| Item | Standard |

| Appearance | White crystalline powder |

| Purity % | 98 Min |

| Loss on drying % | 0.50 Max |

| Sulfate (SO42-) % | 0.05 Max |

| Chloride (Cl) % | 0.07 Max |

| Heavy metals (Pb) ppm | 10 Max |

| Reduzate (D-glucose) % | 0.7 Max |

| PH (10% water solution) | 6.2~7.5 |

| Arsenic salt(As) ppm | 0.2 Max |

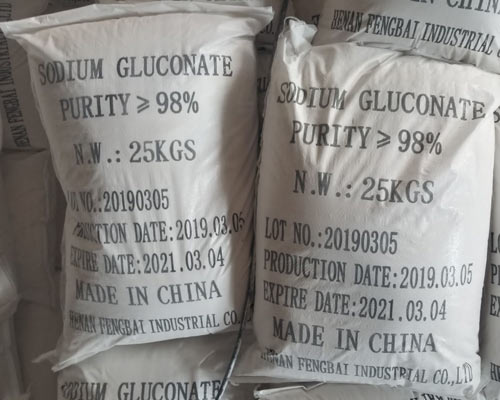

Packing & Loading | 25 kg/PP bag, 26tons in 20’FCL without pallets; 1000kg/Jumbo bag on a pallet, 20MT in 20’FCL; 1150kg/Jumbo bag on a pallet, 23MT in 20’FCL; |

Main Functions of Sodium Gluconate in Concrete

1. Solve the need for retarded setting during high-temperature construction

In summer, high temperatures (≥35°C) accelerate cement hydration, shortening the initial setting time of concrete to 1-2 hours, which can easily lead to cold joints. Adding 0.2%-0.3% sodium gluconate can extend the initial setting time to 4-6 hours, providing ample time for continuous pouring of large concrete volumes (such as bridge caps and equipment foundations), avoiding structural hazards caused by construction interruptions.

2. Optimizing the slump resistance of high-strength concrete

High-strength concrete of C50 and above has a low water-cement ratio. While SNF superplasticizer improves fluidity, it suffers from rapid slump loss at high temperatures (over 30% loss per hour). A 1:3-1:5 ratio of sodium gluconate to SNF can control the slump loss to less than 20%, ensuring the fluidity of concrete from the mixing plant to the construction site (transportation distances of over 50 kilometers), making it suitable for pumping in projects such as high-rise building cores and long-span bridges.

3. Protects rebar and formwork, extending project life

Compared to traditional retarders (such as phosphates), sodium gluconate is non-corrosive to rebar. When used in reinforced concrete projects, it reduces the risk of rebar corrosion caused by retarders. Furthermore, its molecules form a light lubricating layer on the formwork surface, reducing the bond between the concrete and the formwork. This prevents surface damage during formwork removal, improving the appearance of precast components (such as precast wall panels and pipe culverts).

4. Improves late-stage strength development of concrete

Although sodium gluconate delays early hydration, it does not affect late-stage strength. When added at a concentration of 0.1%-0.2%, concrete strength may decrease by 5%-10% after three days, but by 28 days, strength can recover to 95%-105% of baseline strength. In some cases, due to more complete hydration, late-stage strength may even increase slightly (by approximately 5%), thus avoiding the long-term strength loss associated with delayed setting.

Uses of Sodium Gluconate 98% min

- Construction Industry. It can be used as highly efficient concrete set retarder and good water reducer for concrete, mortar and gypsum. Adding a certain amount of sodium gluconate to the cement can increase the plasticity and strength of the concrete, and has a retarding effect, delaying the initial and final setting time of the concrete. Besides, it can improve the strength of concrete.

- Textile Industry. The sodium gluconate manufactured by Fengbai is widely used in the textile industry, such as for dyeing, printing, and treating the metal surfaces of textiles with water.

- Water Treatment Industry. Fengbai sodium gluconate for sale has excellent effects of corrosion and scale inhibition, so it is widely used as a water quality stabilizer, for example, as a series of processing agents for circulating cooling water systems in petrochemical industry, low pressure boilers, and cooling water systems for internal combustion engines.

- Chelating Agent and Cleaning Agent. It can be used as a chelating agent for cement, plating and alumina dyeing industries. Of course, it can be also used as special cleaning agent for steel surface and glass bottles.

- Food Industry. As a kind of food additive, food grade sodium gluconate can used as a substitute for salt , as well as improve the flavor of food.

- Pharmaceutical Industry. It can adjust the acid-base balance in the human body to restore the normal function of nerves.

Why Choose Fengbai

- As a leading manufacturer and exporter in China, Fengbai is an enterprise that integrates scientific research, production, sales and service. And Fengbai has always focused on the production of high-quality sodium gluconate and various water treatment chemicals for more than 15 years.

- Fengbai company has first-class production equipment and technology, as well as modern instrument monitoring system and testing equipment.

- Owning a complete quality management system and quality assurance system. And all of Fengbai chemicals have passed these certification, they are ISO 9001, SGS, HACCP, KOSHER, HALAL, etc.

- Professional Sales Team. We are always committed to providing customers with excellent services and high-quality products. So far, our products have been exported to more than 20 countries and regions, including Indonesia, Vietnam, Singapore, Malaysia, Egypt, Brazil, India, South Africa, Colombia, Chile, Russia, Saudi Arabia, Nigeria, etc.